Unlocking Efficiency – The Role of Rotary Vane Vacuum Pumps in Industry

Rotary vane vacuum pumps are essential tools in various industries, offering reliable vacuum solutions for a wide range of applications. These pumps, including those offered by becker-international, utilize a simple yet effective mechanism to create vacuum pressure, making them versatile and efficient devices.

Understanding Rotary Vane Vacuum Pumps

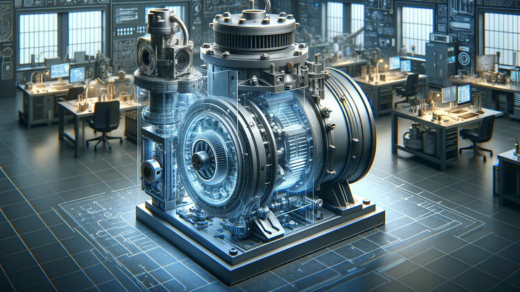

Rotary vane vacuum pumps operate on the principle of positive displacement, where rotating vanes trap air and expel it from the pump chamber, creating a vacuum. This continuous process allows for the removal of air and other gases from enclosed spaces, facilitating processes such as vacuum packaging, degassing, and material handling.

Applications of Rotary Vane Vacuum Pumps

The versatility of rotary Vane Vacuum Pumps makes them indispensable in numerous industries. From manufacturing and medical applications to research laboratories and food processing facilities, these pumps play crucial roles in ensuring product quality, process efficiency, and equipment performance.

Advantages of Rotary Vane Vacuum Pumps

One of the primary advantages of rotary vane vacuum pumps is their reliability. With robust construction and minimal moving parts, these pumps offer long-lasting performance and require minimal maintenance. Additionally, they can achieve high vacuum levels, making them suitable for demanding applications.

Different Types of Rotary Vane Vacuum Pumps

Rotary vane vacuum pumps are available in various configurations to suit different requirements. Single-stage pumps are suitable for general-purpose vacuum applications, while two-stage pumps offer higher vacuum levels and are often used in more demanding processes.

Key Features of Rotary Vane Vacuum Pumps

Modern rotary vane vacuum pumps, such as those manufactured by becker-international, incorporate advanced features to enhance performance and efficiency. These may include variable speed drives, integrated cooling systems, and noise-reducing technologies, providing users with optimal vacuum solutions.

Choosing the Right Rotary Vane Vacuum Pump

Selecting the appropriate rotary vane vacuum pump depends on factors such as required vacuum level, flow rate, and operating conditions. Consulting with experts from becker-international can help determine the most suitable pump for specific applications, ensuring optimal performance and reliability.

Maintenance and Care of Rotary Vane Vacuum Pumps

Proper maintenance is essential to maximize the lifespan and performance of rotary vane vacuum pumps. Regular inspection of components, lubrication of moving parts, and monitoring of operating parameters can help prevent downtime and ensure continuous operation.

Common Applications of Rotary Vane Vacuum Pumps

Rotary vane vacuum pumps find use in a wide range of industries and applications. From automotive manufacturing and electronics production to pharmaceutical processing and HVAC systems, these pumps contribute to efficiency, productivity, and product quality.

Understanding the Operation of Rotary Vane Vacuum Pumps

In rotary vane vacuum pumps, the rotation of vanes within a cylindrical chamber creates suction, drawing air and gases into the pump. As the vanes rotate, they compress the trapped air, expelling it through an exhaust port and creating a vacuum in the process.

Benefits of Using Rotary Vane Vacuum Pumps

The benefits of rotary vane vacuum pumps extend beyond their reliability and efficiency. These pumps offer quiet operation, compact size, and versatility, making them suitable for both industrial and laboratory environments. Additionally, they can handle a wide range of gases and vapors, enhancing their utility in diverse applications.

Environmental Considerations of Rotary Vane Vacuum Pumps

As environmental concerns become increasingly important, the efficiency and eco-friendliness of vacuum pump technologies are gaining attention. Rotary vane vacuum pumps, particularly those with energy-saving features and low emissions, contribute to sustainable manufacturing practices and reduced environmental impact.

Innovations in Rotary Vane Vacuum Pump Technology

Advancements in rotary vane vacuum pump technology continue to drive improvements in performance, efficiency, and reliability. Manufacturers like rotary vacuum pump are constantly innovating to meet the evolving needs of industries and offer solutions that enhance productivity and sustainability.

Industry-specific Applications of Rotary Vane Vacuum Pumps

Different industries utilize rotary vane vacuum pumps for specific applications tailored to their requirements. For example, in the automotive industry, these pumps are used for brake system evacuation and engine testing, while in the food packaging industry, they facilitate vacuum sealing and product preservation.

Choosing the Right Rotary Vane Vacuum Pump for Your Application

Selecting the right rotary vane vacuum pump involves evaluating factors such as required vacuum level, pumping speed, and compatibility with process materials. Working closely with experts from becker-international can help identify the most suitable pump for achieving desired performance and efficiency.

Maintenance Tips for Rotary Vane Vacuum Pumps

Routine maintenance is essential for keeping rotary vane vacuum pumps in optimal condition. This includes checking oil levels, inspecting seals and gaskets, and cleaning filters and exhaust ports. Following manufacturer recommendations and scheduling regular servicing can prolong pump lifespan and prevent costly downtime.

The Role of Rotary Vane Vacuum Pumps in Industry

In conclusion, rotary vane vacuum pumps are indispensable tools in various industries, offering reliable vacuum solutions for diverse applications. With their robust construction, efficiency, and versatility, these pumps play vital roles in ensuring product quality, process efficiency, and equipment performance.