Make Heat Work Smarter with Baffles in Your Powder Coating Oven

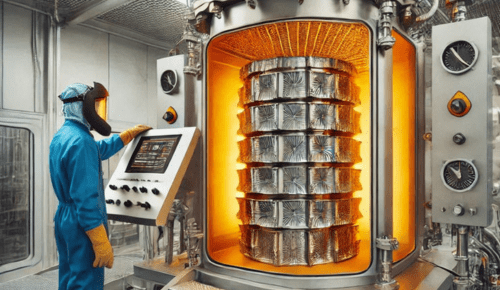

When it comes to powder coating, precision isn’t just about applying the powder perfectly—it’s about making sure the curing process is seamless. Inside a powder coating oven, heat distribution plays a major role in achieving a consistent, high-quality finish. One of the unsung heroes in this process is the baffle. These simple yet ingenious components can make all the difference in how efficiently and effectively your oven operates.

Guiding Heat to Hard-to-reach Areas for Flawless Finishes

Ever noticed areas on coated parts that seem uneven or undercured? That’s often a result of heat not reaching certain sections of the oven effectively. Baffles act like traffic controllers for hot air, guiding it toward areas that would otherwise be overlooked.

In powder coating ovens, parts with complex shapes or varying thicknesses are especially tricky to cure evenly. Without proper airflow, those recessed corners or dense sections might not achieve the necessary temperature for proper curing. By strategically placing baffles, the heat can be directed precisely where it’s needed. This means every part—no matter how intricate—emerges from the oven with a flawless, durable finish.

The beauty of using baffles is that they don’t just fix a problem; they enhance the overall curing process. With heat efficiently guided, the risk of uneven curing diminishes significantly, making your powder coating oven more reliable and consistent.

Balancing Thermal Flow to Eliminate Curing Inconsistencies

In any powder coating oven, maintaining a balanced thermal flow is key to consistency. Hot spots and cold zones can wreak havoc on the curing process, leading to unpredictable results. Baffles can help eliminate these temperature disparities by redistributing heat evenly across the oven chamber.

When thermal flow is balanced, you don’t have to worry about moving parts around mid-cycle or compensating for uneven heat exposure. Baffles ensure that the entire oven maintains a consistent temperature, so whether you’re working with a single large part or a batch of smaller items, every surface cures uniformly.

This balance doesn’t just improve product quality; it reduces rework and waste. By eliminating inconsistencies, you save time and resources, making your powder coating oven a more efficient tool in your production process.

Optimizing Energy Use with Strategically Placed Baffles

Running a powder coating oven can be energy-intensive, especially if the heat isn’t utilized effectively. Without baffles, hot air might circulate inefficiently, leading to longer curing times and higher energy consumption. By installing baffles strategically, you can optimize the airflow to ensure maximum heat utilization.

When the heat is distributed properly, the oven doesn’t have to work as hard to maintain the desired temperature. This not only shortens curing cycles but also reduces overall energy costs. Reliable powder coating ovens with well-placed baffles can achieve the same level of curing efficiency using less energy, making them both cost-effective and environmentally friendly.

Strategic baffle placement can also help in optimizing oven capacity. With better airflow management, you can fit more parts into the oven without sacrificing quality, increasing productivity without increasing operational costs.

Creating a Uniform Environment for Even Powder Application

The curing process begins the moment the powder is applied, and the environment inside the oven determines how well the powder adheres and cures. Without a uniform heat environment, some areas of the coating might appear blotchy or uneven after curing. Baffles help create a consistent thermal environment, which directly contributes to even powder application.

A quality powder coating oven equipped with properly positioned baffles ensures that every part of the surface receives equal heat exposure. This eliminates the risk of uneven finishes, which can happen when some areas are exposed to more heat than others. With baffles in place, you can trust that every coated part will have a professional-grade appearance.

Moreover, maintaining uniform conditions also improves the durability of the coating. When the heat distribution is consistent, the powder fuses evenly, creating a tougher, more resilient surface that can withstand wear and tear.

Protecting Delicate Parts from Overheating During the Process

Not all parts are created equal—some require a gentler approach when it comes to heat exposure. Overheating can damage delicate parts, affecting their structural integrity or appearance. Baffles allow you to fine-tune the heat flow within your powder coating oven, ensuring that sensitive components are shielded from excessive heat.

For example, thinner materials or intricate designs might need less direct heat to avoid warping or scorching. Baffles can deflect the hot air away from these vulnerable areas while still maintaining the overall curing temperature. This kind of precision protects delicate parts, ensuring that they emerge from the oven in perfect condition.

This protective capability of baffles adds another layer of reliability to your powder coating process, making it easier to handle a diverse range of parts without worrying about potential damage.

Enhancing Productivity with Faster and More Reliable Heat Distribution

Time is money in any production environment, and a powder coating oven equipped with baffles can help you save both. By improving heat distribution, baffles enable faster and more reliable curing cycles, which means you can complete more batches in less time.

Faster heat distribution doesn’t compromise quality—in fact, it enhances it. With baffles ensuring even and efficient airflow, each batch is cured to the same high standard. This means less downtime, fewer do-overs, and a more streamlined production process overall.

Compact powder coating ovens, in particular, benefit greatly from baffle systems. By maximizing the use of limited space, baffles allow smaller ovens to achieve the same level of efficiency and performance as larger models, making them a smart choice for businesses looking to optimize their workflows.