The Science and History Behind PEX Pipe: A Revolution in Outdoor Heating

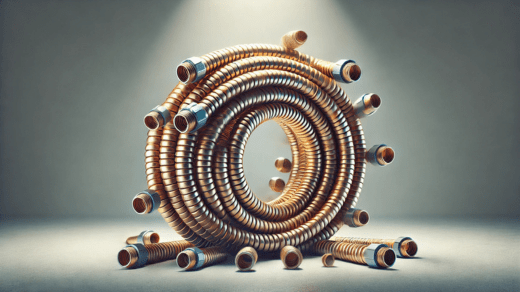

When thinking about modern heating solutions for homes and especially using outdoor boilers, one of the most important components that pop into mind is PEX pipe. Short for cross-linked polyethylene, PEX has found its way into plumbing and radiant heating systems because of flexibility, durability, and ease in installation. But while an insulated PEX pipe might seem like something from science fiction, its history and the science behind it are teeming with innovation and a long history. Let’s dig deeper and see how underground insulated PEX pipe came to be and why it continues to be a popular favorite for outdoor heating systems today.

The Rise of PEX: A Technological Revolt

PEX pipe was first produced in Europe in the 1960s. There had to be the need for an elastic, tough, and reliable substitute for rigid piping materials like copper and steel. The discovery came about when the scientists realized the method for cross-linking the polymer chains of polyethylene. In this process, a material stronger and tougher which does not crack, freeze or corrode. This led to insulated PEX pipe, which is a revolutionary pipe because it offers flexibility, lengthened service life, and an installation process much easier compared to other piping materials.

Though PEX did not take over the American market overnight, its adoption was still gradual in the 1980s and 1990s when there were more conscious people of even more of its advantages. Today, underground insulated PEX is a popular installation for radiant heating systems, piping, and even part of the outdoor boiler installation component.

Why Insulated PEX Pipe is Perfect for Outdoor Boilers

The most common use of PEX today is in outdoor heating systems, especially those that have outdoor boilers. In the case of heating a home or business with an outdoor furnace, there is a need to transfer hot water or steam from the outdoor unit to the building’s heat exchanger. Underground insulated PEX pipe is the perfect solution for this.

Here’s why:

High thermal resistance from the crosslinking process makes PEX perfectly suitable to be carrying hot water over great distances. The insulation that covers PEX pipe further cuts heat loss during water traveling underground, hence using lesser energy when transporting heat from an outdoor boiler is considered to be your building.

Extreme Conditions Durability Outdoor boilers run under extreme conditions-from frozen winters to extremely hot summers. PEX is very resistant to cracking and freezing, which is important when laying pipes underground. The insulated PEX pipe will keep the water hot, while the insulation protects the pipe against the hostile environment, thus providing a long life for the pipe.

Flexibility for easy installation: Underground insulated PEX is very flexible compared to rigid materials like copper. It allows easier and faster installation since it can bend around obstacles without needing additional fittings, thereby reducing the chance for leaks or failures. This flexibility is especially useful in complex layouts or uneven terrains where rigid piping may not work as well.

Cost-Effective: In general, the available PEX pipes are less expensive than the traditional copper or steel. Moreover, it is lighter and quite easy to install. With fewer corrosion and scaling buildups, the repair and maintenance that it needs, in the long run, are reduced.

How Insulation Works in PEX Pipes

Insulated PEX pipe has the “insulation” referring to the outer protective wrap meant to keep the temperature of the water in it, and somewhat the heat loss. This is a feature very important for heating purposes outdoors, where the pipes are covered underground under extreme weather conditions prevailing there.

The material itself usually constitutes foam or fiberglass that features a high resistance to heat transfer. It works in the following ways:

There is no heat loss since the hot water from the outdoor boiler has to go inside the home or business.

The insulation acts as a barrier to environmental factors including UV radiations and freezing temperatures that can weaken the pipe.

It keeps water hot until it reaches the heat exchanger where it will use it to warm.

Quality of insulation purchased on sale for insulated PEX pipe makes all the difference as it will directly affect your performance and efficiency in your outdoor boiler system.

PEX Pipe Today: The Go-To Solution for Outdoor Heating Systems

Today, outdoor PEX is the first choice of installation and upgrading of outdoor heating systems for homeowners as well as businesses. Underground insulated PEX, combined with modern heating technologies, made outdoor boilers pretty efficient, eco-friendly, and cheaper for many.

In such circumstances where the world at large is looking for solutions that will efficiently save energy, PEX pipe has played a huge role in heating homes and minimizing the usage of energy. Its withstanding position against freezings, easy installation, and durability over long periods makes this material timeless.

Whether it is to install an outdoor boiler or to replace some of the older piping, insulated PEX pipe tops your list. There’s no doubt that PEX has changed our thinking about heating and piping systems with its proven reliability and phenomenal performance.

From history to science, PEX pipe can prove on how simple innovations in material technology can make such an impact on energy efficiency and cost savings as well as on sustainability. From its early roots in the 1960s to its widespread use today, the underground insulated PEX really stands at the top of modern heating solutions. If you want to invest in insulated PEX pipes, then what you’re really investing in is the future of efficient heating for your home.

Outdoor PEX: Learn How Outdoor PEX Can Assist Your Boiler System

To see our high-quality outdoor PEX pipe products, look on our outdoor boiler page.